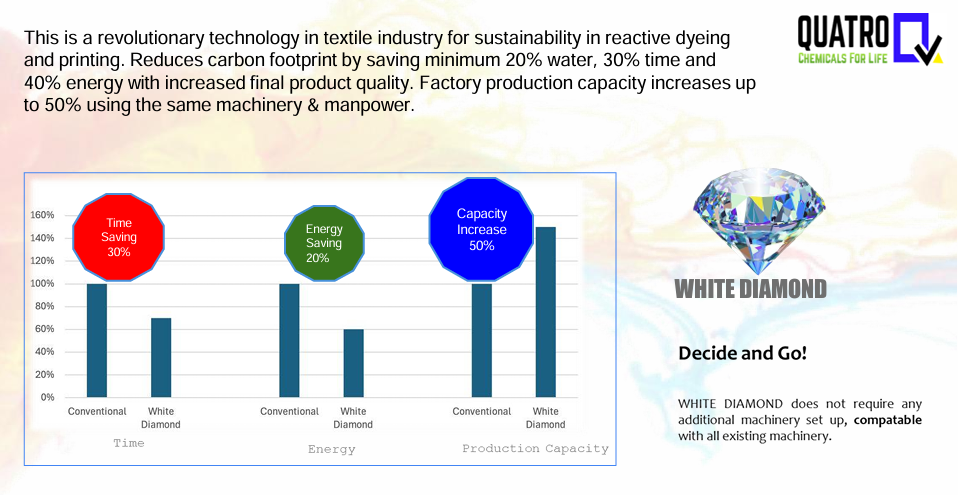

White Diamond is a specialized product that reduces dyeing process time by at least 40%.

It increases capacity while significantly reducing energy, water, labor, steam, and chemical consumption.

It also improves the RFT (Right First Time) dyeing rate.

In pad-batch dyeing processes, it eliminates silicate usage, removing both shade variation and batch-end discrepancies.

Optimizes the dyeing workflow by reducing process time up to 40%, enabling better production planning and faster output.

In conventional processes, 2.2–2.4 dyeing batches are achieved, while White Diamond enables up to 4 batches, resulting in a 40–45% increase in production.

With increased production, nearly double the dyeing output can be achieved with the same energy consumption, leading to approximately 40% reduction in energy costs.

Thanks to high dye fixation, less rinsing is required. Two washes at 80°C are sufficient.

With the same number of workers, 40–45% more production can be achieved compared to standard processes. This results in significantly lower labor cost per kilogram.

High temperatures (e.g., 98°C) are not required in rinsing baths, so steam consumption is reduced.

This decreases natural gas usage, positively affecting gas bills.

Several dyeing chemicals used in standard processes become unnecessary. At least three chemicals are eliminated, which reduces both environmental impact and stock/operational costs.

One of the main challenges in dyeing is the need for shade corrections. In White Diamond, the first-time-right ratio is high (around 98%).

Lower reprocessing rates boost all other savings and contribute to consistent success.

Color continuity between lab and production, and between different production batches, is reliable.

In medium-to-dark polyester dyeing, reductive clearing is no longer required, which shortens the process time, eliminates reductant costs, and reduces environmental impact.

Silicate-free padbatch dyeing is possible.

Waiting time (batch resting) is cut in half, and the difficulty of removing silicate from the fabric is eliminated.